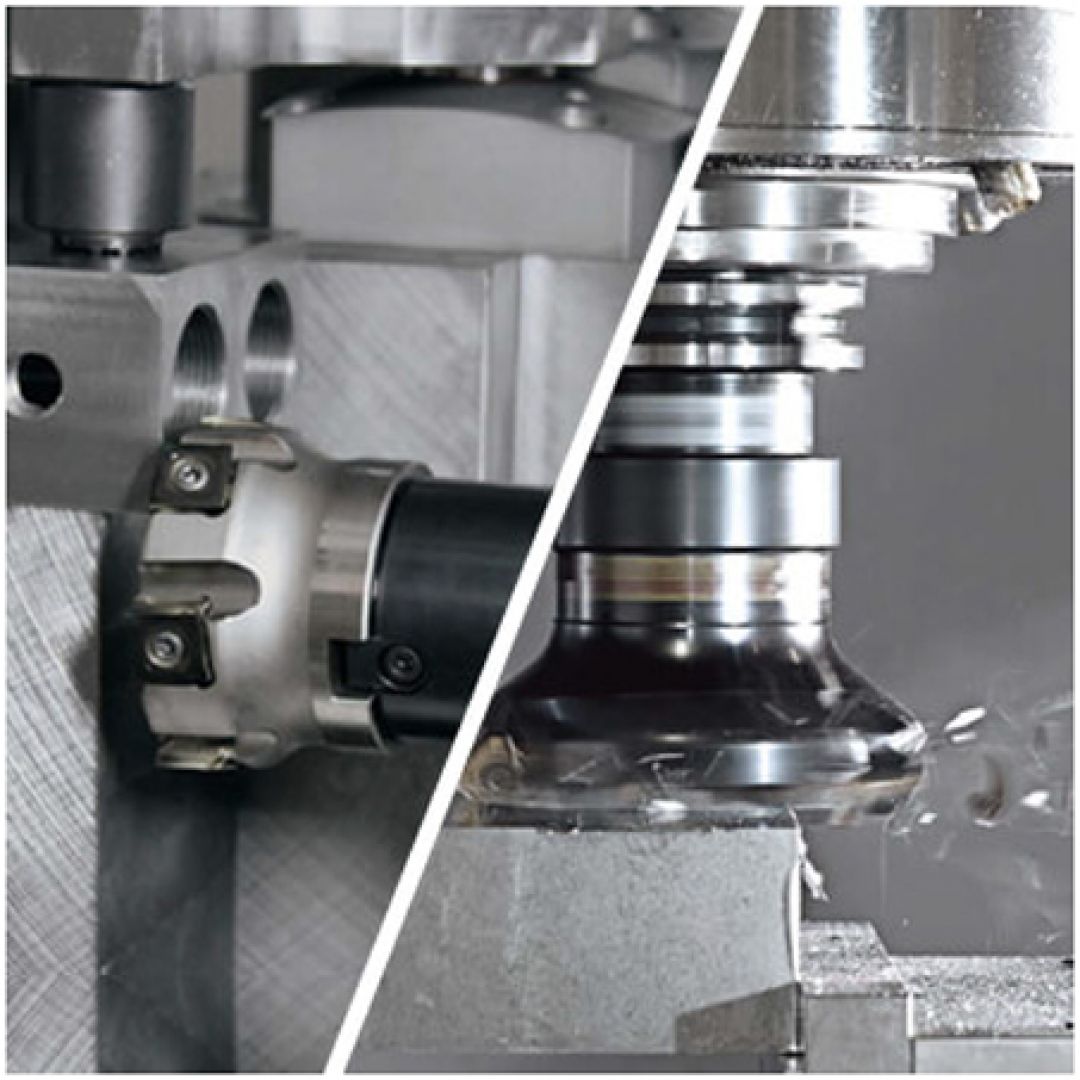

VMC vs HMC

There is no doubt that CNC machines are an extremely efficient means towards achieving streamlined production. With the multitude of options available on the market today, it can get extremely confusing between finding the right CNC machine for your business. In fact, the most common question we hear is what is the difference between vertical machining centers (VMC’s) and horizontal machining centers (HMC’s)? In this article we are going to uncover the differences between the two machining centers as well as discuss some next steps if you are looking for purchasing options.

The Basics

Before being able to compare a VMC to an HMC it is critical to understand how both these machining centers operate. With that being said, the most notable difference between how both these centers operate has to do with the spindle orientation. A VMC uses cutters to remove metal from a workpiece and employs a vertical spindle. Due to the vertical orientation of the spindle, all of the work that is machined by a VMC happens in a vertical work plane. Comparatively, HMCs utilize a spindle that operates in the horizontal work plane. Both of these machines utilize cutters to gradually remove excess metal to shape the final workpiece into the desired final product.

Vertical Machining Centers

When looking at VMC’s there is no doubt that they are the cheaper alternative when compared to their horizontal counterpart. Due to less fixturing and toolholders, many machinists might find that the vertical machining center is a lot easier to operate. Additionally, VMC’s can come in numerous sizes and are well-rounded and practical for jobs such as creating large engines or more precise projects such as creating small bone plates. The primary limitation of VMC’s is their restriction in machining workpieces from multiple sides. Due to the fact that all workpieces are machined on a vertical plane, oftentimes machined pieces need to be flipped many times in order to achieve the final desired product.

Horizontal Machining Centers

In addition to VMC’s, HMC’s are also another very viable option if you are looking to get into machining workpieces. As opposed to their vertical counterparts, horizontal machining centers, although more expensive, definitely offer more versatility in terms of machining workpieces from multiple angles. Due to its unique design consisting of two integrated pallets, which allow for tombstones and fixtures to be attached, this allows access to both the front and sides of a workpiece. Additionally, due to the horizontal orientation, spindle utilization is greatly improved in HMC’s allowing for high levels of efficiency. Lastly, HMCs usually have a larger tool magazine and improved chip flow.

What are the benefits of implementing an HMC or VMC into your workplace?

Now that you know the differences between HMC’s and VMC’s let's take a look at some of the benefits you can expect by choosing to implement either of these machining centers into your manufacturing processes:

Ease of operation

When working with machines such as vertical machining centers, the orientation of these machines allow for easy visibility and allows operators to spot mistakes during the milling process. Additionally due to the computer numerical controls (CNC) attributes of both VMC’s and HMC’s, operators can spend less time manually machining workpieces, and instead rely on the automatic programming of the machine to take care of designing workpieces in their intended form.

Higher Productivity

When it comes to projects such as milling parts for intensive items such as diesel engines, VMC’s and HMC’s are both ideal options for large-part manufacturing. As opposed to doing things manually, these machining centers can facilitate quick production, and promote an overall higher level of productivity.

Reduced overall costs

○ Lastly, when looking at finances, there is no doubt that both HMC’s and VMC’s will allow for huge cost-saving in the long-run. Despite this, if you are looking for a best all in one option, it is recommended to opt for the horizontal machining center as the ratio of replacement shows that one HMC can replace up to three VMC’s. This allows for freed-up workspace which will help reduce your overall manufacturing costs and open up space for other machining equipment without the additional investment of seeking a larger facility.

Where Can You Buy a Vertical or Horizontal Machining Center?

Now that you understand the differences between horizontal and vertical machining centers, now we can discuss some purchasing options available to you. Fortunately at Gizmo Machine Tools, we currently have a variety of options for both horizontal and vertical machines if you are looking to buy a machining center.

As a Canadian corporation we service internationally in buying, selling and trading of machinery. With over 18 years of experience in the manufacturing industry our company focuses on providing customers with an alternative to expensive new machinery, when tooling up for a job or replacing existing capital equipment. If you have any questions or require assistance feel free to contact us today and we would love to help!