MURATEC ML-400 TURNING CENTER

MURATEC ML-400 TURNING CENTER

Available quantity:1

Description

Transforming a production line isn’t just about adding new equipment—it’s about choosing technology that actually makes a difference. The CNC Turning Centers from Muratec, available through Gizmo Machine Tools INC, offer exactly that. These machines aren’t just well-built—they’re built with intention. Every element, from the robust Tail Stock to the smartly designed Chip Conveyor, serves a purpose grounded in real manufacturing demands.

6-IN Chuck

Let’s start with the basics. The 6-IN Chuck isn’t just for show—it allows for adaptable clamping, giving your operators more flexibility when handling different types of materials. Whether you're dealing with aluminum, brass, stainless steel, or tougher alloys, the clamping system delivers consistent grip and repeatable precision. That matters more than most people realize—especially in high-volume metalworking environments where even small misalignments can throw off an entire production cycle.

Tail Stock

Now, the Tail Stock deserves more attention than it typically gets. It offers critical support during long machining operations—particularly useful when you're working with slender or heavy parts that need extra stabilization. It might seem like a small feature, but it can dramatically improve surface finish and dimensional accuracy, especially in precision machining applications where quality control isn’t just a checkbox—it’s a commitment.

One thing that often gets overlooked in similar CNC lathe systems is chip management. The Muratec design team has clearly thought this through. The Chip Conveyor efficiently removes debris from the machining zone, which might sound minor at first, but it significantly reduces the time operators spend cleaning up. That translates to less downtime and more productive hours on the shop floor. And then there’s the integrated Coolant Tank, which honestly might be one of those features you only fully appreciate after running the machine for a few weeks. It keeps tooling temperatures under control, extending tool life and helping maintain tighter tolerances across longer runs.

But all of this would mean less if the machine weren’t properly vetted. And that’s where Gizmo Machine Tools INC comes in. Each unit undergoes a meticulous inspection by experienced specialists who know exactly what to look for. This isn't a “shiny on the outside, mystery on the inside” kind of sale. These machines meet rigorous benchmarks before they ever reach your floor, ensuring long-term reliability—a trait often claimed, but rarely proven in the industrial CNC equipment space.

With the full package of all available manuals, the learning curve becomes manageable. Whether you're new to automated turning centers or you’re just expanding capacity, having proper documentation helps avoid the typical headaches of installation and operation.

Of course, we have to mention—all specifications should be verified by the buyer. That’s standard practice, but it also speaks to a broader philosophy: transparency. You’re not just buying a high- performance machine tool—you’re entering a relationship with a supplier that respects your standards as much as their own.

Specifications

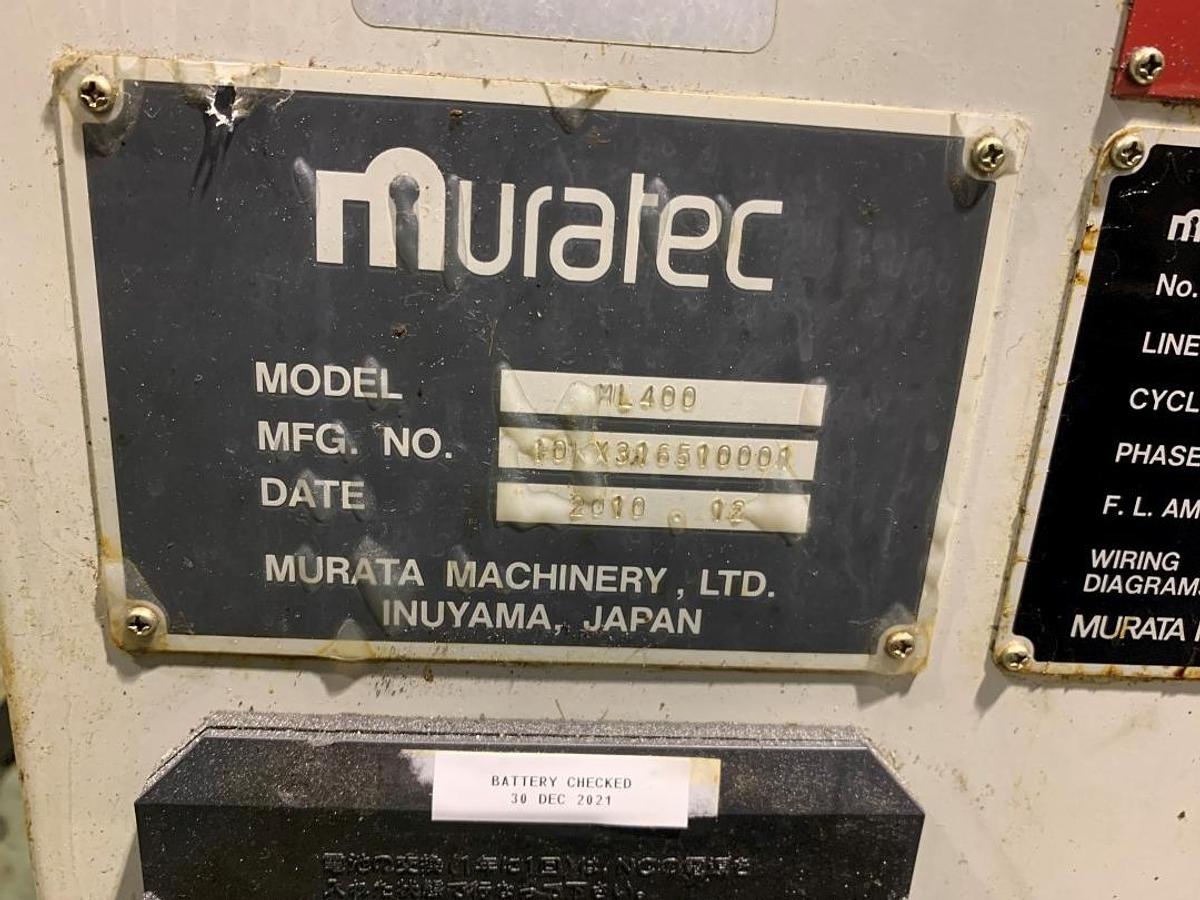

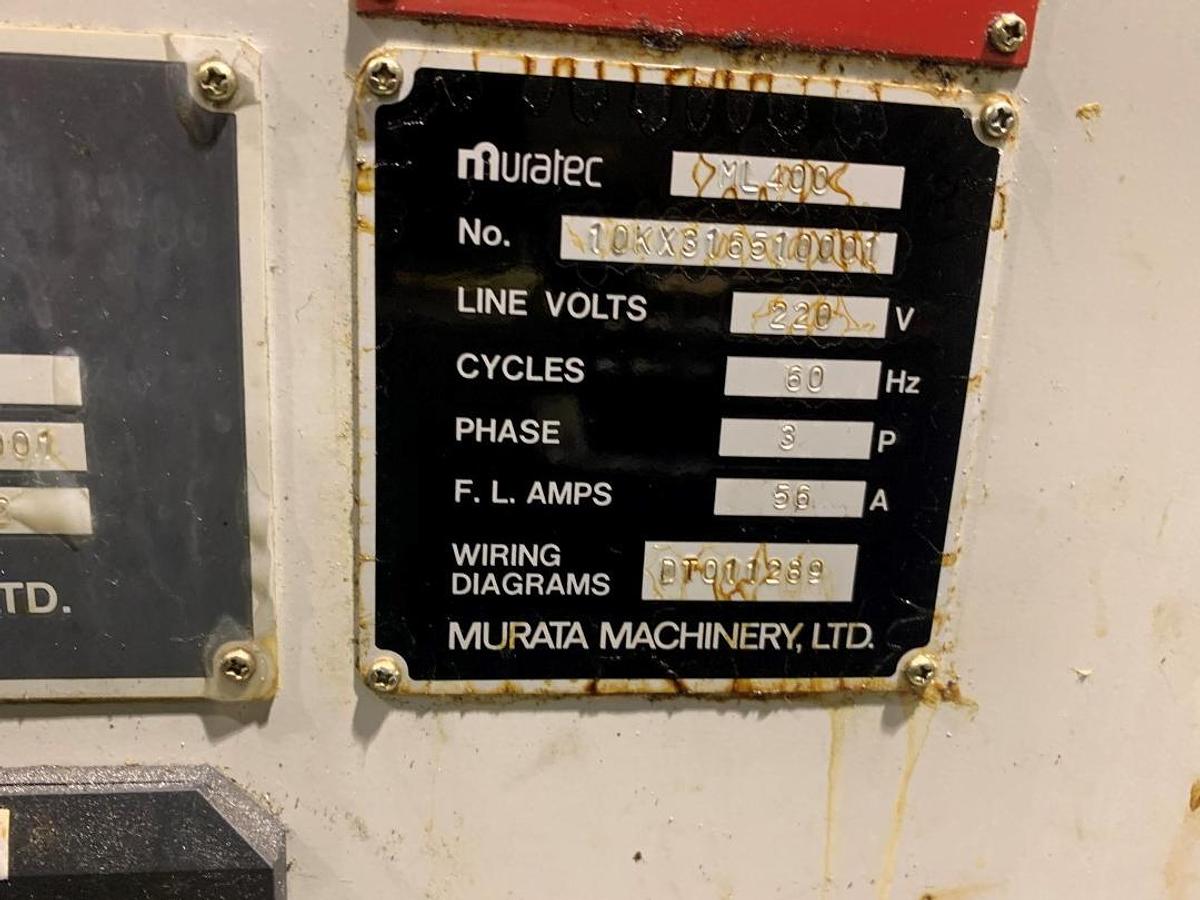

| Manufacturer | Muratec |

| Model | ML-400 |

| Year | 2010 |

| Condition | Used |

| Serial Number | 10KX316510001 |

| Stock Number | TC-MTH-766 |

| MAX. SWING | 13.38 INCHES |

| CHUCK SIZE | 6 IN |

| MAX WORK PIECE SIZE | 7.87 x 15.35 IN |

| TURRET STATIONS | 6 |

| X AXIS STROKE | 5.11 IN |

| Z AXIS STROKE | 16.93 IN |

| TAILSTOCK/QUILL STROKE | 11.81 IN |

| SPINLDE SPEED | 3000 RPM |

| RAPID TRAVERSE X AXIS | 787.4 IPM |

| RAPID TRAVERSE Z AXIS | 1259.8 IPM |

| TAILSTOCK SPEED | 787.4 IPM |

| MACHINE DIMENSION | 66.9 IN x 113.38 IN x 70.07 IN |

| APPROX WEIGHT | 9700.34 LBS |

| GANTRY X AXIS STROKE | 33.46 INCHES |

| GANTRY Y AXIS STROKE | 10.63 INCHES |

Equipped With

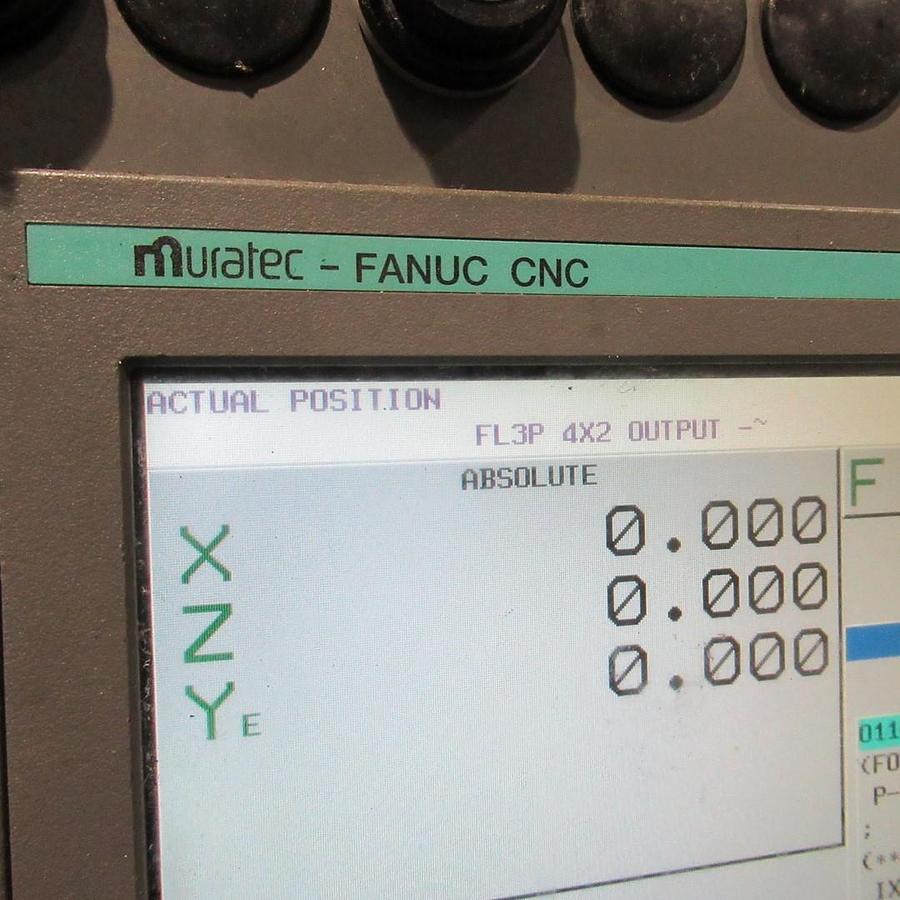

Muratec Fanuc CNC FS-32i

Fanuc Gantry Loader

Tail Stock

Collet Chuck

Chip Conveyor

Coolant tank

All Manuals Available