DOOSAN DMP-500 TWIN SPINDLE 2017 VERTICAL MACHINING CENTER (LOW HOURS)

DOOSAN DMP-500 TWIN SPINDLE 2017 VERTICAL MACHINING CENTER (LOW HOURS)

Available quantity:1

Description

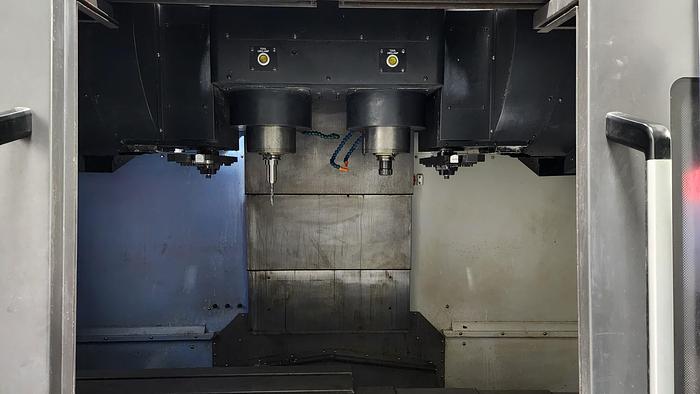

Unlock new levels of efficiency with the DOOSAN DMP-500 Vertical Machining Center, a powerhouse featuring twin spindles and dual ATCs. Designed for high performance, this machine boasts extremely low operating hours and is under power on our floor for your inspection. Benefit from advanced features like 20-bar (230 psi) Through Spindle Coolant, and Air Through Spindle capabilities. Its separate 380-liter (100-gallon) coolant tank comes with a way oil skimmer, and the machine is equipped with screw conveyors on both troughs for efficient chip disposal. Additional standard equipment includes a full enclosure splash guard, telescopic covers, metered piston distributor lubrication, and a portable manual pulse generator. Every unit is inspected rigorously by Gizmo Machine Tools INC to meet the highest quality standards. Complete with Fanuc operator and maintenance manuals, this DOOSAN Vertical Machining Center is your one-stop solution for unmatched industrial machining.

EQUIPPED WITH

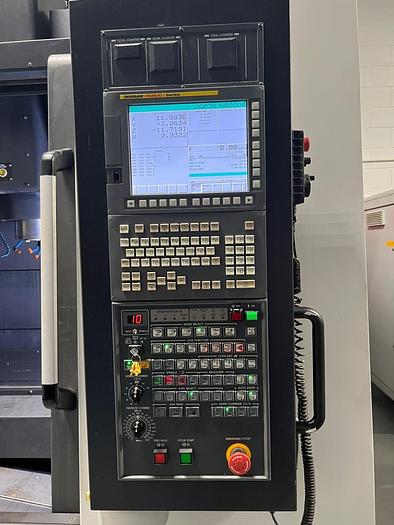

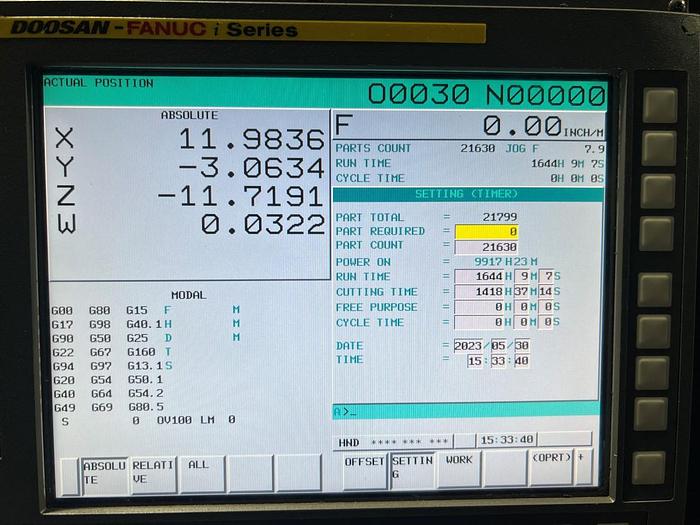

Controller Doosan Fanuc i Series

20 bar (230 psi) Through spindle coolant, Air through spindle

Flood coolant with large separate coolant tank with way oil skimmer (380 liter\ 100 gallon)

Screw conveyors on both troughs for chip disposal

Instruction manual, parts list, and electrical drawings

Fanuc operator and maintenance manuals

Specifications

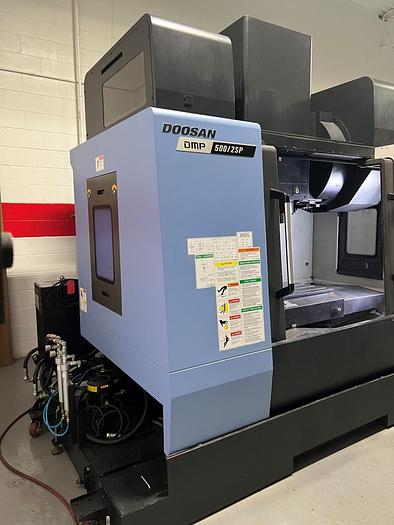

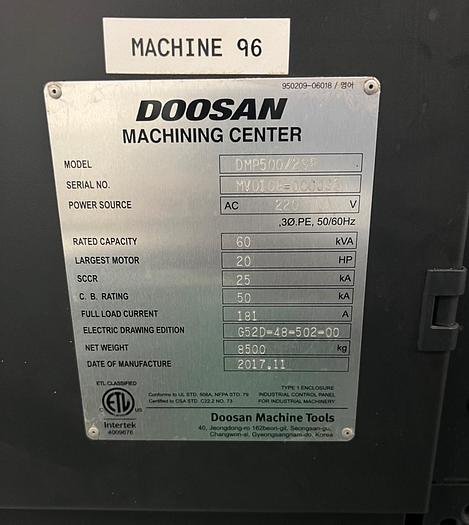

| Manufacturer | Doosan |

| Model | DMP-500-2SP |

| Year | 2017 |

| Condition | Used |

| Serial Number | MV0108-000035 |

| Stock Number | VMC-DMP-741 |

| X axis travel | 40.9 INCHES |

| Y axis travel | 20.5 INCHES |

| Z axis travel W axis travel | 23.6 INCHES |

| Table loading area | 47.2 X 20.5 INCHES |

| Allowable table load | 1763.7 LBS |

| Distance between spindles | 15.74 INCHES |

| Spindle Taper | CAT 40 Big Plus |

| Spindle Speed | 12,000 RPM |

| Number of Tools Tool Shank | 2-24 (24 per spindle) |

| Max. Tool Dia. | 3.5 INCHES |

| Max. Tool Length | 11.8 INCHES |

| Max. Tool Weight | 17.6 LBS |

| X Axis Rapid Traverse Rate | 1,574.8 IPM |

| Y Axis rapid traverse rate | 1,574.8 IPM |

| Z Axis Rapid Traverse Rate | 1417.3 IPM |

| Tool to Tool Time | 1.7 S |