MAZAK SLANT TURN 50N CNC DUAL CHUCK TURNING CENTER

MAZAK SLANT TURN 50N CNC DUAL CHUCK TURNING CENTER

Available quantity:1

Description

The Used Mazak Slant Turn 50N CNC Dual Chuck Turning Center features a MAZATROL T PLUS controller and is equipped with front and rear 3-jaw hydraulic chucks for versatile handling of workpieces. It also includes a chip conveyor for efficient chip management, making it ideal for heavy-duty, high-precision turning operations.

When you’re working in high-demand machining environments, every detail of your setup matters. The Mazak Slant Turn 50N CNC Dual Chuck Turning Center offers more than just solid construction—it brings real flexibility and reliability to your floor. Whether you're managing long production runs or tackling complex precision metal turning jobs, this machine holds its own.

At the heart of it is the MAZATROL T PLUS controller, a system that's been trusted in machine shops for decades. There’s a certain comfort in familiarity, especially when that familiarity includes intuitive programming and proven reliability. For those who’ve used Mazak equipment before, it just... works. And even if you haven’t, the learning curve isn't steep. You’re not battling some abstract interface—you’re working with a system designed to actually support machinists in real-time, on-the- floor conditions.

But the standout here? Definitely the dual hydraulic 3-jaw chucks—mounted front and rear. This isn’t a gimmick. It’s a game-changer for anyone handling large or complex work pieces. Dual chucks mean added stability, better alignment, and improved grip on both ends. You’re reducing the risk of chatter and deflection, which, for anyone dealing with industrial lathe systems, is no small concern. You can take on longer shafts or intricate pieces without needing additional support equipment. It gives you options, and options mean flexibility in quoting and fulfilling contracts.

Then there's the chip conveyor—sometimes seen as an afterthought, but here, it’s built into the value of the machine. If you’ve ever had to manually clean chips out of a CNC turning center during a long shift, you already know why this matters. Continuous chip removal not only keeps the work area cleaner but also helps maintain more consistent cutting conditions. Less heat, less tool wear, and less downtime.

Now, let’s be realistic. This is a used CNC lathe, not fresh off the factory floor. But that's not necessarily a downside. In fact, machines like the Mazak Slant Turn 50N often hit their stride after a few years—once quirks are worked out and real-world performance has been tested. With proper inspection and routine maintenance, this unit has the potential to offer years of dependable service in demanding shop conditions.

So, who’s this machine really for? Probably someone who values efficiency over flash, someone who’d rather have a robust dual chuck turning machine that can handle roughing and finishing in one setup, instead of juggling two machines and extra fixturing. It's ideal for contract manufacturers, job shops, or anyone scaling up their heavy-duty CNC turning operations without jumping into new-equipment pricing territory.

Just keep in mind—as with all used equipment, specifications should be verified by the buyer. But in this case, what you're really looking at is a proven performer with smart design, trusted controls, and the kind of features that matter more the longer you run it.

Specifications

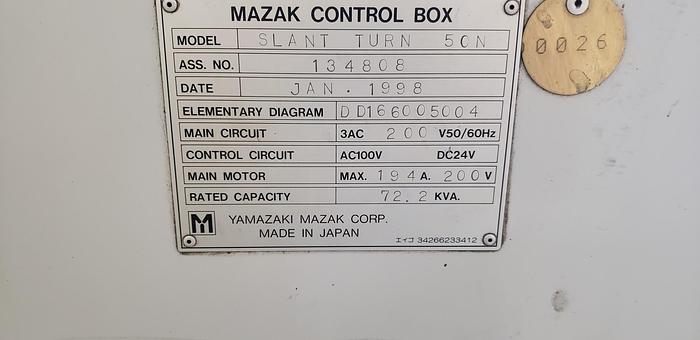

| Manufacturer | Mazak |

| Model | SLANT TURN 50N |

| Year | 1998 |

| Condition | Used |

| Serial Number | 134808 |

| Stock Number | TC-MZK-907 |

| TRAVELS X | 22.64" |

| TRAVELS Z | 82.09" |

| MAX SWING | 31.69" |

| Chuck Size | 15" |

| MAX TURNING LENGTH | 80" |

| MAX CUTTING DIAMETER | 16.5" |

| SWING OVER CARRIAGE | 22.05" |

| DISTANCE BETWEEN CENTERS | 89.25" |

| SPINDLE BORE | 8" |

| SPINDLE SPEED | 1600 RPM |

| TOOL TURRET | 10 POSITIONS |

| Machine dimensions | 228.94" X 105" X 107.36" |

| Approx. Machine Weight | 30,830 lbs (Approx.) |

Equipped With

Equipped With

Controller: MAZATROL T PLUS

CHIP CONVEYOR

FRONT AND REAR 3-JAW HYDRAULIC CHUCKS