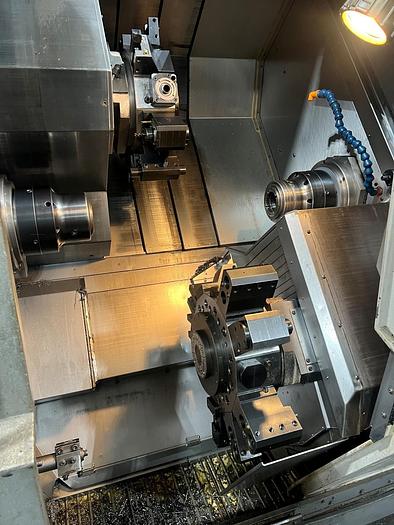

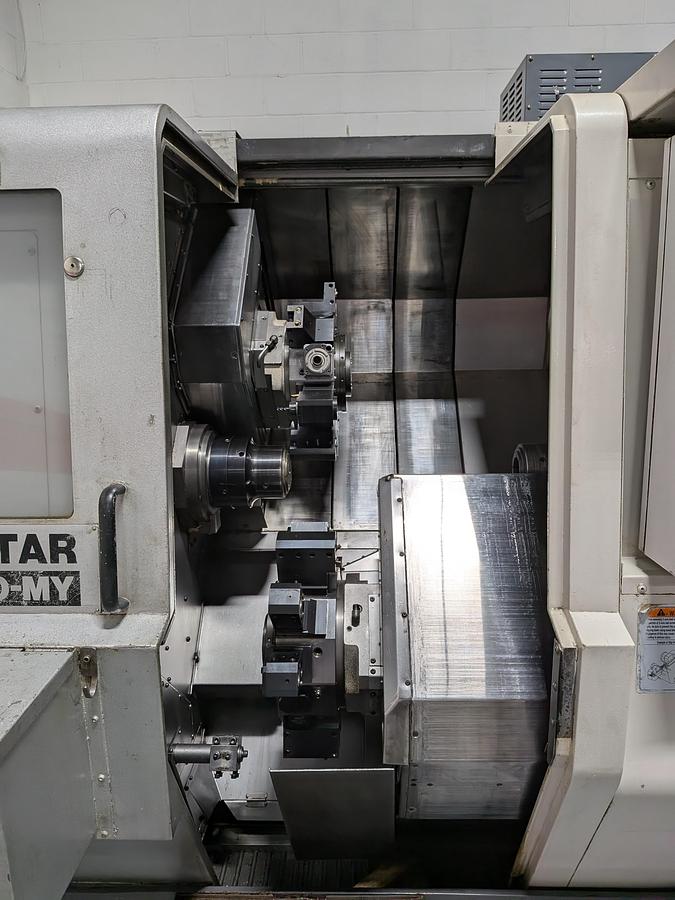

2004 Okuma Howa Twin Star LT200-MY Turning Center

2004 Okuma Howa Twin Star LT200-MY Turning Center

Available quantity:1

Description

When you think of precision machining, finding a turning center that seamlessly blends reliability with versatility can be a challenge. The 2004 Okuma Howa Twin Star LT200-MY emerges as a noteworthy contender, especially for operations aiming to enhance their turning capabilities without venturing into brand-new equipment territory.

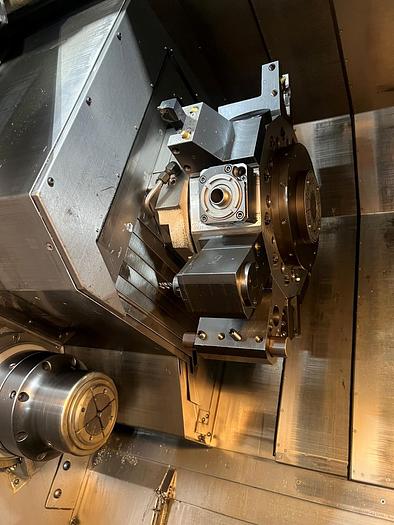

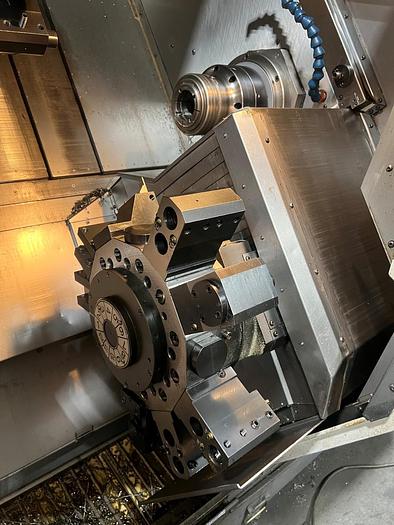

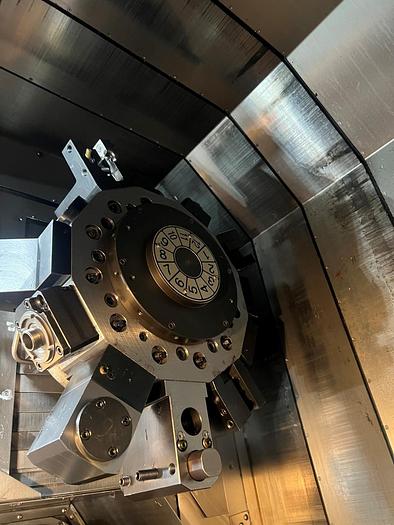

At its core, this machine is equipped with the Okuma OSP-P100 CNC controller, a system known for its user-friendly interface and consistent performance. For machinists familiar with Okuma's ecosystem, this controller offers a sense of familiarity, reducing the learning curve and facilitating smoother operations. One of the standout features of the LT200-MY is its dual turret (FT and RT) configuration, each boasting a 12-station capacity. This setup allows for simultaneous machining processes, effectively reducing cycle times and increasing throughput. The live tooling capability, with speeds ranging from 50 to 6000 RPM, further enhances its versatility, accommodating a variety of complex tasks without the need for multiple setups.

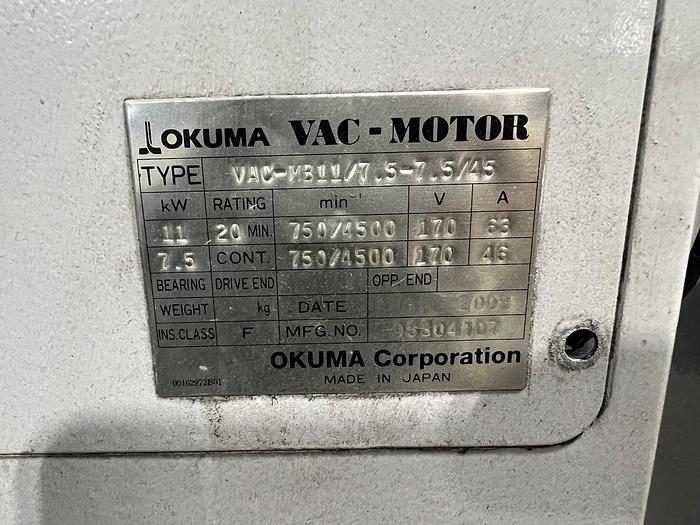

The machine's spindle speeds reach up to 4500 RPM, powered by a robust 15 HP main spindle drive. This ensures that it can handle a diverse range of materials, from softer metals to more challenging alloys. The bar capacity of 2 inches is adequate for many standard applications, making it a suitable choice for shops dealing with medium-sized components.

In terms of physical dimensions, the LT200-MY offers a maximum swing over bed of 15.75 inches and a maximum turning diameter of 8.27 inches. The maximum turning length stands at 21.26 inches, with a distance between spindles of 37.80 inches. These specifications indicate a machine designed for a broad spectrum of tasks, from simple turnings to more intricate components.

Additional features include a chip conveyor, which aids in maintaining a clean work environment by efficiently removing debris. The coolant tank and high-pressure coolant system play a crucial role in

temperature management, ensuring tools remain cool during operations, thereby extending their lifespan and maintaining machining accuracy.

While the LT200-MY is a used model, it's essential to recognize the value it brings to the table. Machines like this, when maintained properly, can offer years of dependable service. It's always advisable for potential buyers to verify specifications and assess the machine's condition to ensure it aligns with their operational needs. If you are looking to buy used 2004 Okuma Howa Twin Star LT200-MY Turning Center, Gizmo Machine Tools is your best bet. Its features cater to a range of machining tasks, making it a viable option for shops looking to expand their capabilities without the significant investment of new machinery.

Specifications

| Manufacturer | Okuma Howa |

| Model | Twin Star LT200-MY |

| Year | 2004 |

| Condition | Used |

| Serial Number | 109521 |

| Stock Number | MAC-LTH-OKH-154 |

| X Axis (Both Turrets) | 7.56" |

| Z Axis(Both Turrets) | 27.56" |

| Max. Swing over bed | 15.75" |

| Max. Turning diameter | 8.27" |

| Max swing over cross slide | 12.2" |

| Max distance between spindles | 37.80" |

| B-axis (sub-spindle) | 28.74" |

| Max bar capacity | 2" |

| Main spindle speeds | 4500 RPM |

| Main spindle drive | 15 HP |

| Turret capacity (both turrets) | 12 |

| Max Live Tool Speed | 6000 RPM |

Equipped With

Okuma OSP-P100 CNC Controller

High Pressure coolant system

2x Collet chucks

Extra Collets

4 axial and 4 radial Live Tools

Misc Tool holders

Chip Conveyor

Coolant Tank