NIIGATA HN-50C Horizontal Machining Center

NIIGATA HN-50C Horizontal Machining Center

Available quantity:2

Description

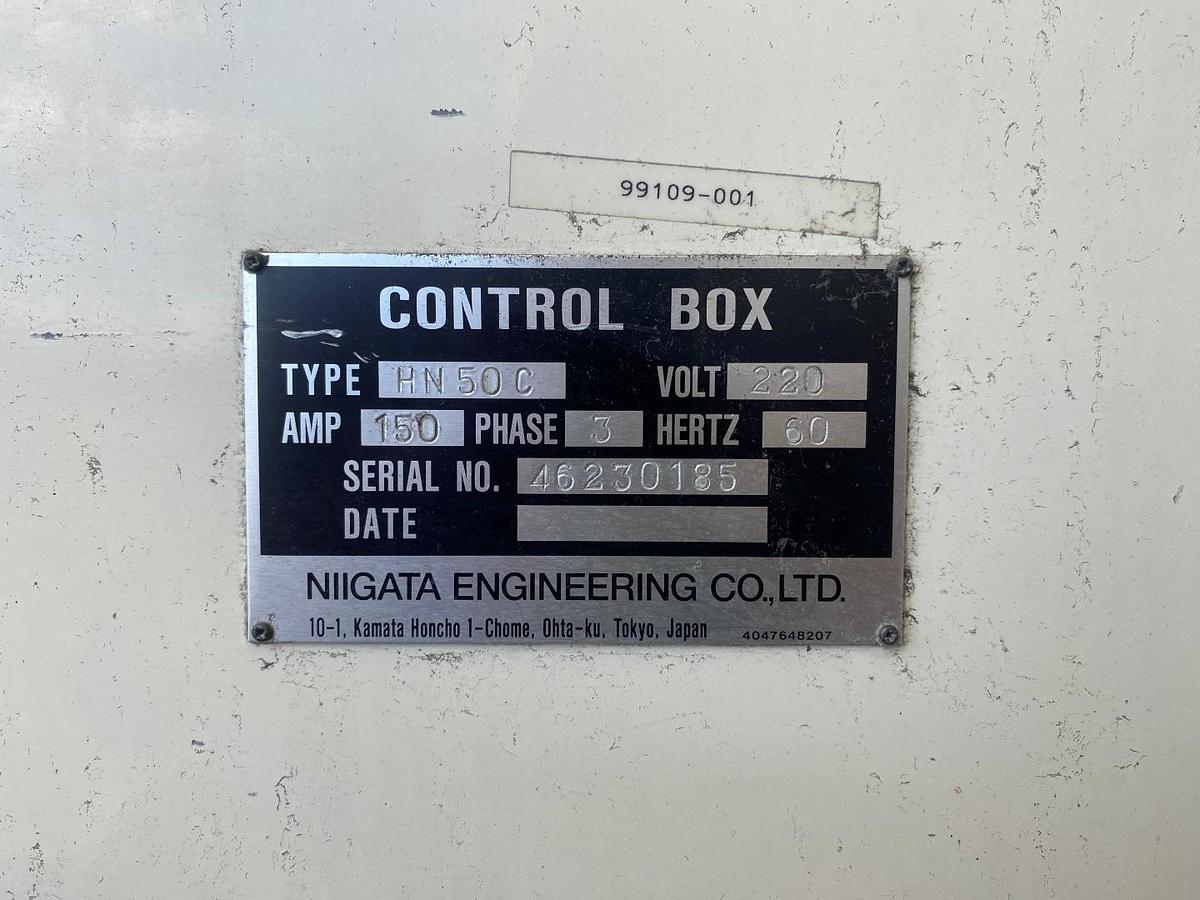

The 2001 Niigata HN-50C Horizontal Machining Center (Serial No. 46230185) delivers high-precision performance with a 4-axis setup and a powerful CAT 50 gear-head spindle. Known for its rigidity and reliability, this model is ideal for heavy-duty milling, complex part production, and long-term durability in demanding manufacturing environments.

Equipped with a Fanuc 16i-M controller, 40-tool ATC, through-spindle coolant, probe, and chip conveyor, it offers smooth automation and reduced downtime. Complete maintenance records are included, ensuring peace of mind and consistent operation.

With its combination of speed, torque, and stability, the Niigata HN-50C remains a trusted choice for shops seeking to increase productivity and handle both small batch and high-volume machining with precision.

Specifications

| Manufacturer | Niigata |

| Model | HN-50C |

| Year | 2001 |

| Condition | Used |

| Serial Number | 46230185 |

| Stock Number | HMC-NIG-0185 |

| Cutting Feed Rate | 1–10,000 mm/min (0.04–394 in/min) |

| Rapid Traverse (X/Y/Z) | 24 m/min (945 in/min) approx. |

| Spindle Torque | Low gear: ~650 N·m (480 ft-lb), High gear: ~210 N·m (155 ft-lb) |

| Spindle Power | 25 HP, 230 V AC |

| Spindle Taper | CAT 50 |

| Max Spindle Speed | 5000 RPM (2-speed gear head) |

| ATC | 40 tools |

| Max Table Load | 700 kg (1540 lbs) |

| Pallet Changer | Twin pallet shuttle system |

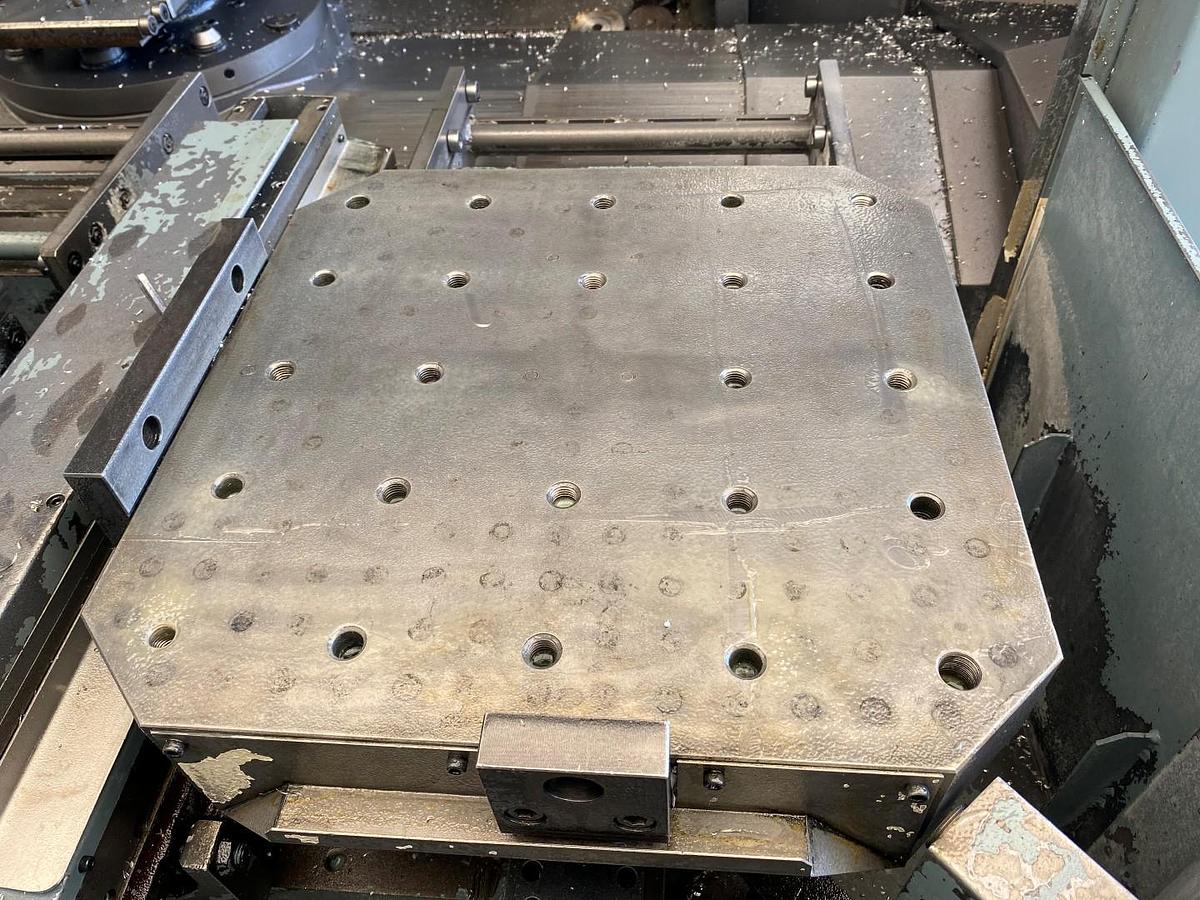

| Table Size | 500 mm pallet (19.7 in) |

| Z Axis Travel | 580 mm (22.8 in) |

| Y Axis Travel | 716 mm (28.2 in) |

| X Axis Travel | 800 mm (31.5 in) |

| Number of Axis | 4 |

| Machine Weight | ≈ 13,000 kg (28,600 lbs) |

Equipped With

• Fanuc 16i-M

• Through Spindle Coolant

• Probe

• Chip Conveyor

• All Maintenance Records